A professional product developed in Germany to ensure the reliability of SCR systems.

Basic benefits

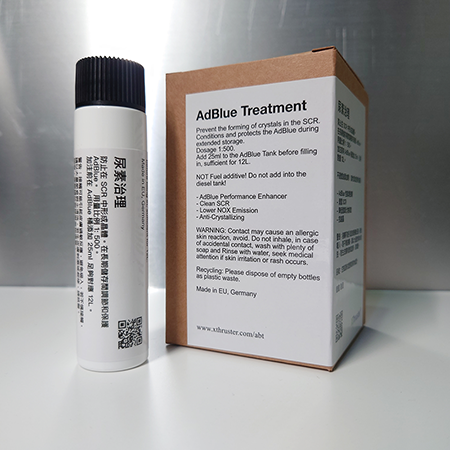

Adding 25ml before filling is enough to mix with 12.5L of AdBlue®.

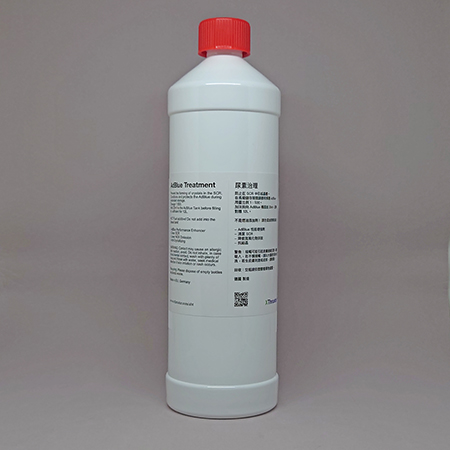

Adding 100ml before filling is enough to mix with 50L of AdBlue®.

Corresponding packaging sizes can be provided based on customer requirements.

AdBlue® is a registered trademark of the Verband der Automobilindustrie e.V. (VDA).

Our document will provide recommendations based on the best knowledge available. However, the handling and application of the content are not legally binding as they are beyond our control. We reserve the right to make modifications for improvement or progress.

Due to the combustion process of diesel engines, exhaust gas recirculation (EGR) devices are often installed to reduce unburnt fuel carbon particles and decrease nitrogen oxide (NOx) emissions. This is because a large amount of unburnt fuel carbon particles entering the exhaust system can lead to an increase in exhaust pipe temperature, which makes the generation of nitrogen oxides (NOx) easier.

In order to further reduce the nitrogen oxide (NOx) emissions from diesel vehicles, automotive companies have introduced diesel engine exhaust treatment fluid – urea, for use in the vehicle’s exhaust system. By utilizing urea, which decomposes into ammonia at high temperatures, the nitrogen oxide (NOx) is then reduced to water and nitrogen through the introduction of ammonia, and subsequently emitted into the environment.

Selective Catalytic Reduction (SCR) refers to a device that uses urea to improve the exhaust emissions of diesel vehicles.

Urea has different representative names in different regions, such as AdBlue® in Europe, DEF (Diesel Exhaust Fluid) in the United States, or nitrogen oxide reducing agent in China. They all refer to the same product. AdBlue is composed of 32.5% urea and 67.5% deionized purified water, which is a liquid product used for exhaust gas treatment of diesel vehicles.

However, there are sometimes issues with the application of SCR devices in vehicle settings, and the most common problem is urea crystallization.

When urea is not thermally decomposed by high-temperature exhaust gas, natural sedimentation of urea may occur. This may be due to the evaporation of water in the urea solution, causing urea crystals to form, or the formation of adhesive substances during the reaction process of urea, causing crystals to form in the nozzles or pumps of the SCR system or even in the SCR catalyst.

Such urea crystallization phenomenon reduces the conversion rate of nitrogen oxides (NOx), leading to increased pollution emissions. It can also result in uneven spraying due to partial blockage of the urea nozzle, causing an increase in urea consumption. In severe cases, it can even lead to nozzle blockage and abnormal NOx reduction in the entire SCR system.

AdBlue Treatment is a professional product from Germany designed to ensure the proper functioning of the SCR (Selective Catalytic Reduction) system in diesel vehicles and reduce maintenance costs associated with the system.